Why Every Factory Owner Needs Expert Contacts in Custom Metal Fabrication

Collaborative Post

Manufacturing is a highly dynamic and competitive environment where efficiency and innovation are hallmarks of success. Factory owners need reliable partnerships with external service providers. Custom metal fabrication experts often play an important role in keeping operations smooth and adaptable. In this blog, we will look at why building relationships with custom metal fabricators should not be discounted as part of an effective manufacturing strategy.

Custom Components to Meet Specific Requirements

No two factories are alike in terms of equipment needs or production demands, and custom metal fabrication accounts for this variability. Fabricators come to the rescue when store-bought components fall short of expectations (or simply do not exist at all) by creating precise, tailor-made parts that fit seamlessly together. Expert fabricators from Armes Precision specialize in creating tailored machinery to meet the specific requirements of each factory, whether that means designing tools with niche applications or fully customized machinery systems. Their expert fabricators make sure that functionality fits seamlessly within your products to fulfill those unique demands. Factory owners who use custom components gain significant competitive advantages from doing so, including optimizing production processes without being limited by standard solutions. Custom solutions may be what separates leaders from followers.

Unparalleled Durability and Quality

Quality is very important when it comes to machinery and its parts, with frequent breakages adding unnecessary costs and stopping productivity. Custom metal fabrication services use only top-grade materials like high strength steel, aluminum or specialty alloys designed specifically to withstand wear and tear for use in production. Experienced fabricators conduct strict quality control checks throughout their process to deliver components with unparalleled durability that help factory operations run more smoothly for longer while minimizing downtime costs and increasing ROI. When custom components are made by professionals they become assets over years instead of liabilities.

Adaptability in Meeting Scaling Demands

Factories frequently adapt their operations in response to market demands, and custom metal fabrication partners excel at being flexible enough to adapt quickly to those changes. From scaling production lines or meeting unexpected operational hurdles, these experts can quickly modify, expand, or upgrade components as required without delays due to finding generic parts that don't quite match what the factory needs. As well as provide invaluable design insight that allows factory owners to implement long-term strategies with short-term fixes.

Cost-Efficiency in the Long Run

While custom-built components may seem more costly initially, they do end up saving more in the long run. Premade generic parts often compromise size, material quality and adaptability leading to frequent replacement and maintenance expenses. Custom solutions on the other hand are tailored for longer service lives while expert fabricators optimize designs with cost-efficient material usage ensuring every inch of raw material serves a purpose. Eliminating hidden costs associated with subpar parts that fail production needs altogether.

Conclusion

Owning and managing a factory can be challenging work as every day brings new obstacles and important decisions to be made. Building relationships with custom metal fabrication services should not just be seen as a luxury but rather seen as important investments to scale success and remain competitive, productive and profitable. Trusting fabricators provides tailored parts, ensures higher quality support, scalability, and cost-effective innovation to help keep your machines operating at maximum potential.

—End of Collaborative Post—

✨ New Series: How to Become an Early Riser

- Discover key methods to make early rising a habit

- How to wake up early + energized every morning

- Morning routines for health + success

Free self-development courses

👇

Tap on any of the courses below to start learning how to:

- boost your productivity (with GTD),

- get focused (with Deep Work),

- or learn the art of influencing others (with the How to Win Friends & Influence People course.)

All for free.

👇

Free life guides

👇

Best-selling Self-development courses by Dean Bokhari

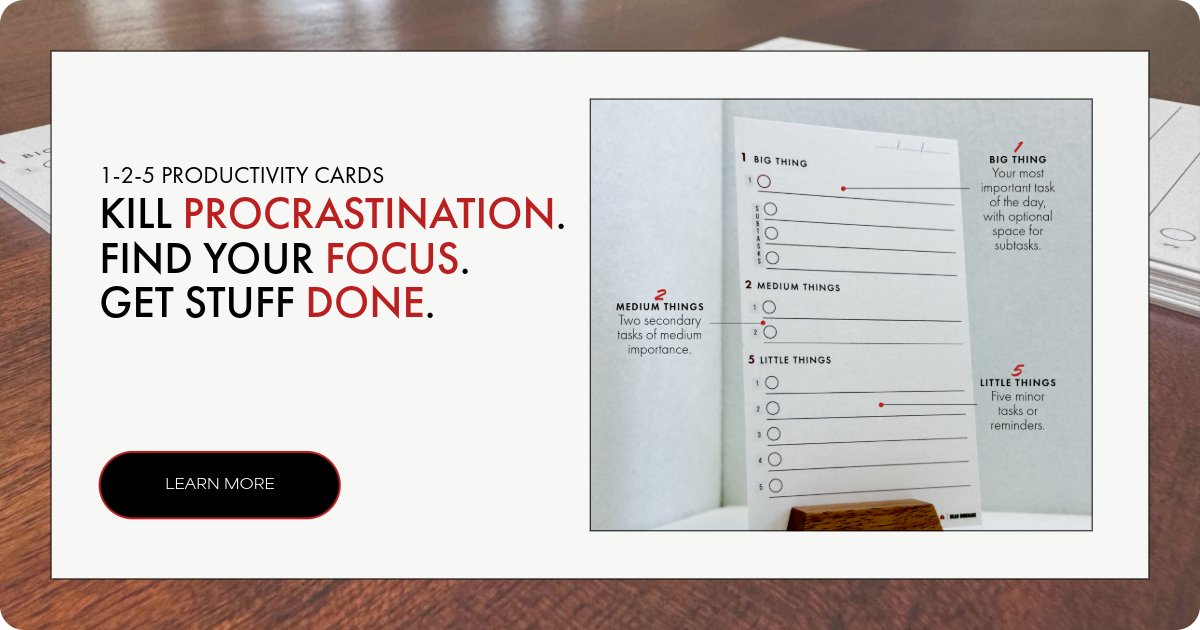

Kill procrastination.

|

Get stuff done.

|

Get motivated.

|

Connect with anyone.

|

freshly pressed:

Top Audiobooks narrated by Dean Bokhari on audible | |

Book summaries

- The Power of Habit by Charles Duhigg

- 12 Rules for Life by Jordan B. Peterson

- Presence by Amy Cuddy

- Leaders Eat Last by Simon Sinek

- The ONE Thing by Gary Keller, Jay Pasan

- Deep Work by Cal Newport