How To Keep Your Manufacturing Lines As Reliable As Possible

COLLABORATIVE POST

Proactive And Preventive Maintenance Is Crucial

The machines that you use to shape your materials into your final products are the heart of your production process and should be given the same amount of care. Breakdowns can massively disrupt production flow, and even smaller issues can result in loss through defective products and wasted materials. Schedule proactive and preventive maintenance, as well as inspections, to ensure machine health is a constant priority. Work with the suppliers of your manufacturing machines to learn about which parts need replacing most often so you can keep a supply of them on hand, too.

Select The Right Materials And Components

Reliability begins with product design, of course. It’s established well before the manufacturing process begins. As such, make sure that you choose high-quality, well-tested components, and take a look at how they are made, such as the PCB manufacturing process, so that you can evaluate their place in your own manufacturing line. Choosing the right materials and components can significantly reduce failure rates by preventing problems from appearing downstream when you begin integrating them into your design. Of course, all components and materials have their own failures, so being aware of them can help you troubleshoot more effectively when making your own products, too.

Carry Out Rigorous Quality Checks Down The Line

The earlier that you’re able to catch issues, the less money and time you can waste before they’re resolved. As such, quality control checks should not be a step carried out only at the end-of-the-line, but rather they should be done at multiple stages so that you’re better able to detect problems where they originate. Nowadays, automated vision systems and AI-driven inspection technologies can detect even subtle defects that human eyes might miss. When quality assurance is woven through the whole process, you can decrease scrap while improving consistency.

Standardize Your Workflows

Consistency is one of the cornerstones of reliable production. Whatever you can do to find the most efficient and effective methods allows you to minimize the variability and thus the chances of failure. When you find the right operating procedures, etch them in stone with manuals and training that can help you quickly teach the standardized method across the board. Automating parts of the production line can be just as effective in reducing human error, of course, but the technicians of those automated steps are subject to the same need for standardization.

Every production line is subject to the potential for inefficiencies, mistakes, and failures. What you can and should do, however, is make sure that you’re addressing them often, routinely cleaning them up and sharpening the production line across the board.

— End of collaborative post —

✨ New Series: How to Become an Early Riser

- Discover key methods to make early rising a habit

- How to wake up early + energized every morning

- Morning routines for health + success

Free self-development courses

👇

Tap on any of the courses below to start learning how to:

- boost your productivity (with GTD),

- get focused (with Deep Work),

- or learn the art of influencing others (with the How to Win Friends & Influence People course.)

All for free.

👇

Free life guides

👇

Best-selling Self-development courses by Dean Bokhari

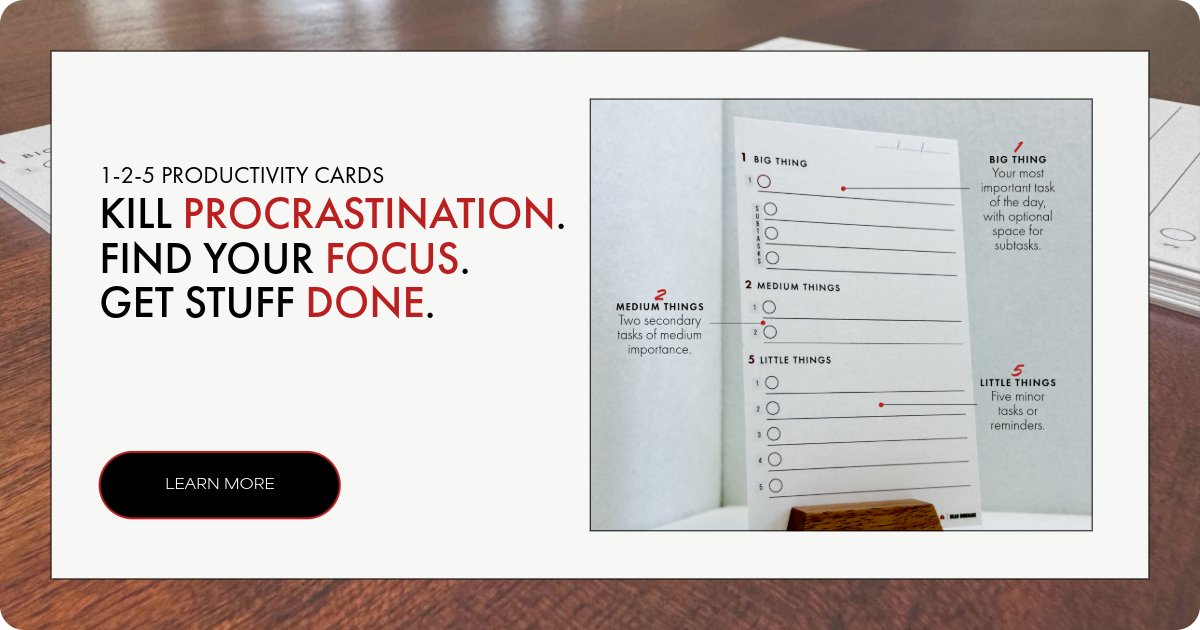

Kill procrastination.

|

Get stuff done.

|

Get motivated.

|

Connect with anyone.

|

freshly pressed:

Top Audiobooks narrated by Dean Bokhari on audible | |

Book summaries

- The Power of Habit by Charles Duhigg

- 12 Rules for Life by Jordan B. Peterson

- Presence by Amy Cuddy

- Leaders Eat Last by Simon Sinek

- The ONE Thing by Gary Keller, Jay Pasan

- Deep Work by Cal Newport